The application of rotary evaporator is mainly in the scientific research and production process of pharmaceutical, chemical, biological products and other industries. Its functions are evaporation, concentration, crystallization, drying, separation and solvent recovery.

In recent years, the application of rotary evaporators has even expanded to the cooking industry. The use of a rotary evaporator to heat liquids retains volatile aromatic hydrocarbons that are easily lost through heating, making the perfect combination of modern cooking and laboratory instruments.

The following Jordan introduces several application cases of rotary evaporators.

Extraction of Cbd Oil by Rotary Evaporator

Cbd Oil is the main chemical component in plant cannabis and a non-addictive component in cannabis. The application of cbd oil in the medical field is mainly based on its protective effect on the nervous system. Cbd Oil exerts analgesic and anti-inflammatory effects through dual inhibition of cyclooxygenase and lipoxygenase, and the effect is stronger than the well-known and widely used aspirin.

The Specific Steps for the Extraction of Cannabidiol Are As Follows:

(1) Take the extracted parts of cannabis (the extracted parts are the parts containing cannabidiol such as leaves, branches and leaves, hemp seeds, etc.) as raw materials, and after crushing, use 60-70% ethanol solution for heat reflux extraction for 2-3 times (For the first extraction, ethanol solution with 7-8 times the mass of the raw material is added, and the ethanol solution with 5-6 times the mass of the raw material is added for the other extractions), each reflux extraction is 1.5-2.5 hours, the extracts are combined, and concentrated under reduced pressure to recover ethanol , get ethanol extraction concentrated liquid extract;

(2) In step (1) ethanol extraction and concentrated liquid extract, first add water 2-3 times the volume of the liquid extract, mix well and then add an alkaline solution (sodium hydroxide, triethylamine, ammonia water or triethanolamine aqueous solution) Adjust the pH value to 11-12, then reflux for 2-3 times, and there is no cannabidiol leaching in the filter residue. Combine and filter the extracts, remove the filter residue, adjust the pH of the filtrate to 7 with dilute hydrochloric acid, and add an equal volume of chloroform- Petroleum ether solution (prepared by mixing chloroform and petroleum ether in a volume ratio of 1:1-1:2) is extracted 3-4 times, cannabidiol is extracted into the organic solvent phase layer, collected and merged with the organic solvent phase layers, and the organic solvent is recovered , get cannabidiol crude paste;

(3) Add ethanol with a mass concentration of 20-30% to the crude cannabidiol cream of step (2), form a suspension and pass it through a polyamide resin column, and elute impurities with pure water after loading until the effluent is Colorless, then wash the polyamide resin column with an ethanol solution with a mass concentration of 40-50% until the effluent is colorless, and then use an ethanol solution with a mass concentration of 70-80% to collect cannabidiol, collect in bottles, and identify by thin layer. The eluent containing the cannabidiol target substance is then combined, and the ethanol is concentrated and recovered to obtain a polyamide chromatography cannabidiol concentrate;

(4) The cannabidiol concentrate in the polyamide chromatography of step (3) was mixed with neutral alumina by dry method, and applied to a neutral alumina column. Ether is prepared by mixing 1:3 by volume) eluting and removing impurities, and then using chloroform-methanol-tetrahydrofuran solution (chloroform, methanol and tetrahydrofuran are prepared by mixing 8:1:1 or 10:0.5:2 by volume) Elution of cannabidiol, collecting the eluate containing the target substance of cannabidiol, and concentrating to obtain crude cannabidiol, the content of which is greater than 60%;

(5) Dissolve the crude cannabidiol in step (4) with methanol, pass through an amino-bonded silica gel column, a cyano-bonded silica gel column or a phenyl-bonded silica gel column, pressurized column chromatography, and the mass concentration of the bonded silica gel column After equilibrating with 20% methanol solution, use methanol solution with a mass concentration of 40%-50% to wash 2-3 column volumes, and then use a methanol solution with a mass concentration of 65-70% for cannabidiol elution, and TLC identification , elute until there is no cannabidiol spot, carry out thin-layer chromatography identification to the methanol eluent with a concentration of 65-70%, combine the eluent containing cannabidiol, and concentrate;

(6) Dissolving the concentrate in step (5) with acetone, adding glacial acetic acid, mixing evenly, leaving it to stand open for crystals, suction filtration, and drying the crystals at low temperature to obtain cannabidiol.

In this method, step (4) can be replaced by: mixing the polyamide chromatographic cannabidiol concentrate in step (3) with alumina by dry method, applying it to a neutral alumina column, after loading the sample, eluting impurities with water, After the impurities are eluted with a mass concentration of 70-80% ethanol until colorless, the cannabidiol is eluted with a mass concentration of 50-60% tetrahydrofuran ethanol solution, the eluent is collected, and concentrated to obtain a crude cannabidiol product.

The Advantages and Technical Effects of This Method:

The purpose of adding an alkaline solution in this method is to enhance the water solubility of cannabidiol, extract it into water during reflux, and at the same time make tetrahydrocannabinol into a salt, which is easy to remove during extraction, and the addition of alkaline substances is combined with organic solvent extraction. The process removes impurities such as THC in the ethanolic extract of cannabis and increases the content of cannabidiol in the crude extract.

Preparation of Onion Extract by Rotary Evaporator

Onion is a characteristic vegetable that integrates nutrition, medical treatment and health care, and is known as the "Queen of Vegetables" in Europe and the United States. Onion extract contains many active substances such as volatile oil and flavonoids, which have physiological functions such as anti-inflammatory and antibacterial, prevention of chronic bronchitis, treatment of edema, diarrhea, expectorant, diuresis, hypoglycemia and prevention of cardiovascular disease. In-depth research on onion will provide new materials for the development and utilization of natural medicines such as anti-aging, anti-oxidation, hypoglycemic, hypolipidemic, anti-thrombotic, anti-cancer, etc., and contribute to human health.

The preparation method of onion extract, the steps are as follows:

(1) fresh onion is weighed and washed, cut into filaments, dried in an oven, pulverized with a pulverizer, sieved to obtain dry powder;

(2) Mix the onion with the extraction agent (ethanol) according to the raw material, the ratio is 1: 15-20 (g/ml), reflux for 2-3 times, the extraction temperature is 65-75°C, and the extraction time is 2-4h , During the extraction process, the raw materials are stirred intermittently for 2-3 times every 0.5h, 3-5min each time, after the extraction process, the feed liquid is filtered out and combined;

(3) put the extract into a rotary evaporator and concentrate under reduced pressure, concentrate to 10% of the total volume, recycle the extractant, decolorize the activated carbon, and filter; first extract with petroleum ether to remove fat-soluble substances, and then use ethyl acetate Ester extraction 3 times, combined filtrates, concentrated and dried to powder;

(4) 60-70 times the volume of 3% (v/v) sulfuric acid aqueous solution is used for reflux hydrolysis for 1.5-2 h, then rotary evaporation, and the obtained feed liquid is pumped into the polyamide adsorption column, and the sample flow rate is 1 mL/min. , adsorbed for 30min, washed with 3-5 times the volume of distilled water to remove impurities; eluted with 80% ethanol, the elution flow rate was 1mL/min, collected the ethanol eluent; concentrated under reduced pressure with a rotary evaporator to collect the ethanol eluent, recovered solvent to obtain onion extract, and freeze-dried onion extract freeze-dried powder of concentrated solution;

(5) Freeze-dried powder of onion extract is obtained after freeze-drying, and the main component is quercetin as detected by HPLC, and the purity reaches 80%-95%.

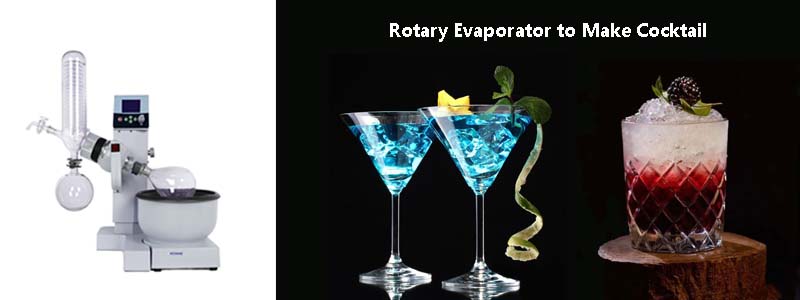

Rotary Evaporator to Prepare Cocktails

We all know that there are many ways to make cocktails, but there is one method you may have never heard of, and that is molecular bartending. In recent years, molecular bartending has developed rapidly and has been widely used in major bars, and is also highly sought after by bar culture lovers.

Molecular bartending is the preparation of ingredients for cocktails with the help of a rotary evaporator. It is based on the characteristics of rotary evaporators that can distill ethanol at room temperature to extract natural ingredients from fruits, petals or other foods. So as to adjust the taste and color of the cocktail. Because the extraction is carried out at room temperature, it is said that the natural ingredients of the material are not destroyed to the greatest extent.

Small Rotary Evaporator for Making Cocktails

A large number of studies have shown that the aroma components of fruits are mainly composed of organic components such as lower alcohols, esters, aldehydes, etc. Most of these organic compounds can be extracted from pulp or pulp with ethanol. Taking blueberry as an example, the main components of blueberry aroma are linalool, (E)-2-hexenal, α-terpineol, hexanal and methoxyphenyl oxime.

Extraction process of blueberries: use a juicer to make blueberries into juice, and then mix with an appropriate amount of brandy. The mixture was placed in sample vials and distilled through a rotary evaporator. The distilled ethanol was collected for use, and the residual water was evaporated. The remaining liquid in the bottle is then mixed with pre-prepared ethanol to make the cocktail.

Extraction of Capsicum Color by Rotary Evaporator

Chili peppers are native to Mexico and Central and South America. The indigenous people of these lands, the Indians, first began to grow chili peppers, and later spread to the world.

The darkest peppers, perfect for natural food coloring. This natural pigment extracted from peppers is called "capsanthin" and has been widely used in cakes, ice creams, medicines, beverages, and even lipsticks. Based on practical verification and component analysis, capsanthin has relatively stable properties, bright color, good colorability, and most importantly, it is safe and non-toxic, and also has certain medical value. Therefore, capsanthin is now recognized as a relatively safe pigment by humans. The WHO even ranks capsanthin as a class A pigment.

There are many ways to extract capsanthin from peppers, and one of the most common and classic methods is Soxhlet extraction. First, the peppers are deseed, chopped and sun-dried. This step is conducive to further processing, storage and transportation. Next, soak the processed peppers in dilute alkali for a period of time to remove the spiciness, filter and then rinse with water until the pH value is about 7, take out the peppers and dry them again for use.

The peppers that have been removed from the spicy treatment are wrapped in filter paper and can be placed in a Soxhlet extraction equipment for Soxhlet extraction with organic solvents (many types of organic solvents can extract capsanthin, including ethanol, butane, acetone, etc.) . Take the extract after Soxhlet extraction, add it to a rotary evaporator or a parallel concentrator for concentration treatment, and then heat and dry the concentrate to obtain a crude product of capsanthin.

Extraction is a crucial step for the extraction and analysis of capsanthin or other natural products. This not only puts forward high requirements for the fast and efficient extraction equipment, but also requires that the extraction equipment can meet various experimental conditions - taking the extraction of capsanthin as an example, capsanthin can be extracted by a variety of organic solvents , and which solvent to choose depends on the different requirements of the experimenter for the properties of the final extracted capsanthin, which requires the extraction equipment to support the use of multiple solvents at the same time. For other types of natural products, it is especially critical that the extraction equipment can provide suitable temperature and pressure at any time according to the different analytes.

ZZKD has accumulated a lot of technology and experience in the field of rotary evaporators for many years, and can provide very convenient and efficient rotary evaporators.

The above are some of the applications of the rotary evaporator that Jordan introduced to you this time. In addition, we also sell other equipment such as short path distillation, vacuum drying oven, freeze dryer. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain, United Kingdom and Thailand. If you want to know about our products, or want to buy our equipment, please feel free to contact us, ZZKD will provide you with the best price for rotary evaporators.