ZZKD Machinery Instrument Equipment Co., Ltd. is a comprehensive manufacturer specializing in R&D, production, sales, laboratory, and biochemical pharmaceutical equipment, especially extraction equipment, reaction equipment, drying equipment, etc. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States and Spain.

ZZKD stainless steel reactors include stainless steel reactors, high pressure reactors, hydrothermal synthesis reactors and decarboxylation reactors.

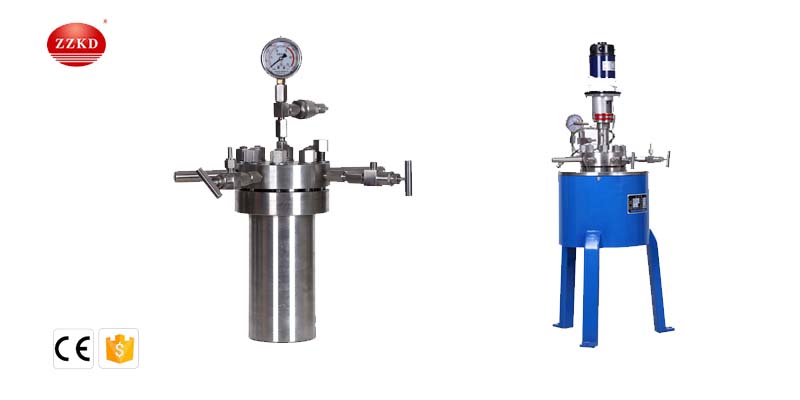

Hydrothermal Synthesis Reactors And High Pressure Reactors

ZZKD stainless steel reactor is usually made of 304 high-quality stainless steel material that meets GMP standards. The equipment is mainly composed of three parts: tank body, jacket and stirring system. The stirring form is multi-frame stirring. The seal adopts sanitary mechanical seal, and the interface adopts ISO standard fast speed. Clamp-mounted type, the inner surface is mirror polished, and the outer surface is multi-selected by sandblasting, frosting, and cold-rolled primary color matt treatment.

Advantages and characteristics of ZZKD stainless steel reactor:

1. Excellent mechanical properties

Due to the strong mechanical properties of stainless steel, the reactor made of stainless steel can withstand higher working pressure and deformation, so it can withstand larger solid materials.

2. Fast heating speed

Stainless steel reactor is a reactor used for physical or chemical reaction. It needs to have high thermal conductivity and cooling. The advantage of stainless steel is that the heating and cooling speed are relatively fast.

3. Excellent processing performance

The processing performance of stainless steel is very good, and it can be processed into different shapes and structures according to the actual process requirements.

4. High temperature resistance

The reaction kettle needs to face different high temperature environments. In general chemical and physical reactions, the temperature is as high as 600 degrees Celsius. In high temperature environments, stainless steel materials can still be used normally.

5. Strong corrosion resistance

The stainless steel material itself contains elements such as chromium and nickel, and has good corrosion resistance. It can still maintain good corrosion resistance when it is made into a reaction kettle.

The role and application of stainless steel reactor:

The main function of the stainless steel reaction kettle is to provide a reaction place and maintain certain conditions, so that the chemical reaction process can be carried out in a predetermined direction, and a qualified reaction product can be obtained. Almost all process equipments contain reactors, so how to choose suitable reactor series, establish operating conditions and design reasonable and reliable stainless steel reactors to meet the needs of the increasingly developing process industry is of great significance.

The stainless steel reaction kettle is composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, a shaft sealing device, and a support. The materials are generally carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel) alloys and other composite materials; ZZKD stainless steel reactors are usually made of 304 high-quality stainless steel that meets GMP standards, and other materials can be customized.

The stirring forms of stainless steel reactors generally include anchor type, paddle type, turbine type, propeller type or frame type.

Different sealing types of stainless steel reaction kettles can be divided into: packing seals, mechanical seals and magnetic seals. The heating method is electric heating, and the cooling method is jacket cooling and inner coil cooling.

Stainless steel reactors are used in petroleum, chemical industry, rubber, pesticides, dyes, medicine, food, and pressure vessels used to complete vulcanization, hydrogenation, alkylation, polymerization, condensation and other processes, such as reactors, reactors, decomposition pots, polymerization Kettle etc.

Stainless steel reactor operating procedures:

1. Check whether the kettle, agitator, rotating parts, auxiliary equipment, indicating instruments, safety valves, pipelines and valves meet the safety requirements.

2. Check whether the water, electricity and gas meet the safety requirements.

3. Before feeding, the agitator of the reaction kettle should be turned on, and the material should be added to the reaction kettle. The amount of feeding should not exceed the technological requirements.

4. Open the return valve first, then open the intake valve. Gradually increase the pressure, and the pressure in the jacket must not exceed the specified value.

5. Open the cooling water valve first, and then open the water inlet valve.

6. For the circulating water vacuum pump, the pump should be turned on first and then the water should be supplied. When the pump is stopped, the pump should be stopped first and then the water should be stopped, and the accumulated water in the pump should be removed.

7. Check the operation of the reactor at any time, if any abnormality is found, it should be shut down for maintenance.

Precautions when using stainless steel reactor:

Most materials in stainless steel reactors are hazardous chemicals. If the material is a material with a low self-ignition point and flash point, once it leaks, it will mix with air to form an explosive mixture. If it encounters a fire source (open flame, spark, static electricity, etc.), it will easily cause fire and explosion; once the material is toxic, it will produce If it leaks, it will lead to poisoning and suffocation; if the material quality is not up to standard, there is also the possibility of explosion.

1. Mechanical impurities enter the reactor, causing partial conflict and heat, resulting in the decomposition and explosion of the reactor. Handling: Be careful not to drop mechanical impurities.

2. The increase of gas oxygen content in the process system will lead to the differentiation and explosion of the reactor. Treatment method: Strictly control the oxygen content in the process system.

3. The collision between the agitator blades and the reactor wall can cause partial overheating, which can lead to the decomposition and explosion of the stainless steel reactor. Treatment method: Improve repair quality and part quality.

4. The wear and heat of the bearing parts lead to overheating and temperature rise, resulting in the decomposition and explosion of the reactor. Treatment method: Strictly check the quality of spare parts and improve the quality of repair.

5. Too many catalysts or too fast feeding speed, and the instantaneous temperature rises too fast, resulting in the decomposition and explosion. Treatment: Strictly control the amount of catalyst, and the feeding should be uniform.

Therefore, in the process of using the reactor, it is necessary to strictly follow the operation manual and select the correct instrument and catalyst. During the reaction, it is necessary to check various instruments from time to time to ensure the normal operation of the reactor.

If you want to know about our products, or want to buy our instruments, please feel free to contact us, ZZKD will provide you with the best price for stainless steel lab reactors.