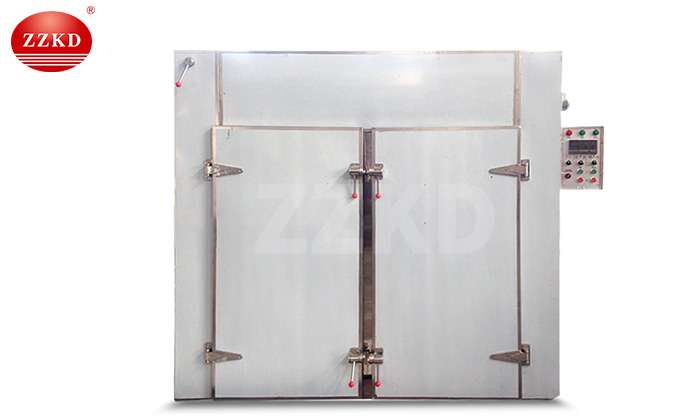

Our hot air circulation drying oven is made of stainless steel with hot air circulation system, which is used for drying fruits and vegetables, suitable for industrial production, also known as industrial fruit and vegetable drying machine.

What is a hot air drying oven?

The air circulation system of the hot air circulation drying oven adopts the fan circulation air supply method, and the air circulation is uniform and efficient. The circulating air supply motor drives the wind wheel through the heater to send out hot air, and enters the inner chamber of the dryer through the air duct. The used air is sucked into the air duct and becomes the recirculated air source for heating.

The principle of industrial fruit drying machine

The working principle of the industrial fruit drying machine is that the circulating air supply motor (using a non-contact switch) drives the air source to drive the air wheel through the heater to send the hot air out, and then enter the oven through the air duct. the inner chamber and then suck the used air into the air. The air duct becomes the air source for recirculation and heating, ensuring uniformity of indoor temperature. When the temperature value fluctuates due to the opening and closing of the door, the air supply circulation system quickly resumes operation until it reaches the set temperature value.

The composition of the industrial fruit drying machine

The industrial fruit drying machine is composed of angle steel, stainless steel plate and cold steel plate. The insulation layer is filled with high-density aluminum silicate wool, which ensures the thermal insulation of the drying box and the safety of users. Heaters can be installed on the bottom, top or both sides. Use digital display smart meters to control temperature.

Industrial vegetable drying machine structure

1. Shell: electrostatic powder coating on the surface of 1.5mm cold-rolled steel plate;

2. Inner tank: 1.2mm mirror stainless steel plate;

3. Solid state relay: Japan Omron;

4. Insulation layer: ultra-fine temperature-resistant glass fiber wool;

5. Sensor: A-grade PT100 platinum resistance;

6. Heating method: nickel-chromium alloy electric heater

7. Temperature control instrument: "AISET" intelligent digital temperature controller, directly input, display, control temperature, over temperature alarm, protection, set temperature and current temperature window display at the same time; heating, alarm, time, fuzzy control;

8. Observation window: There are glass observation windows on each door of the box, which can observe the test state in the box at any time;

9. The rear of the box is equipped with an exhaust port that can be closed or the displacement can be adjusted to change the air.

Industrial vegetable drying machine use steps

1. After connecting the power supply, turn on the power switch and press the start fan button to observe whether the air inlet and outlet are in the correct direction. If there is no wind or the air volume is small, the phase connection is reversed (the motor is reversed), please adjust the direction in time to make the motor run normally (the running direction should be consistent with the red arrow);

2. Put the product into the oven, and close the door; Automatic: set in order: baking temperature, baking time.

3. Then press the start button, at this time the oven will automatically heat and wind automatically.

4. After reaching the set temperature, wait for the timer to automatically count, and when it reaches the set time (M is minutes), the power supply will be automatically cut off (heating and ventilation are automatically turned off). After baking, the product can be taken out at this time;

Advantages of industrial vegetable drying machine

1) The oven consists of a chamber body, a heating system, an electrical control system, an air supply system, and a protection system.

2) The box is made with advanced equipment, the industry's manufacturing process, the lines are smooth, and the appearance is elegant.

3) The material of the studio plate is galvanized steel plate (the user can choose stainless steel plate), the material of the outer box is high-quality cold-rolled steel plate, the product shell is sprayed with environmentally friendly scratch-resistant and wear-resistant paint, and the overall design is beautiful and elegant, suitable for various industries and places. color match.

4) The shelves in the studio can be produced according to the user's requirements and the number of shelves.

5) The thermal insulation material between the studio and the outer box is high-quality ultra-fine glass fiber thermal insulation cotton, the thickness of the thermal insulation layer: >70mm, the thermal insulation effect is good, and the high-performance insulation structure. There are inner cavity, inner shell, ultra-fine glass fiber, and air interlayer air duct from inside to outside, and the heat loss of the inner tank is small. The unique structure of the inner box, the outer box and the door box greatly reduces the heat transfer from the inner cavity.

6) High-performance sealing material and unique sealing structure are used between the door and the door frame, which has good sealing, high temperature resistance and aging resistance.

7) The air duct in the box adopts a double circulation convection system, consisting of a wind wheel and a circulating air duct. The heat of the electric heaters placed on the left and right sides of the box is discharged to the middle through the left and right side air ducts, and then sucked by the top wind wheel after drying. , to form a reasonable air duct, so that the hot air can be fully convection, so that the temperature in the box can be uniform to the maximum extent. The ability to heat the air flow is increased, greatly improving the temperature uniformity of the drying oven.

8) The heater adopts metal electric heating tube, which has fast heating and long life.

Industrial vegetable drying machine feature

1. The Industrial vegetable drying machine has high efficiency and saves energy.

2. There is an air duct in the oven, and the material is dried evenly.

3. The oven runs stably, adopts automatic temperature control, and is easy to install and maintain.

4. It has a wide range of applications and can dry various materials, such as fruits, vegetables, Chinese herbal medicines, etc. It is an ideal drying equipment.

Application of industrial vegetable drying machine

Industrial vegetable drying machine is widely used in raw materials, traditional Chinese medicine, powders, granules, vegetables, fruits, etc.

Parameter

Model | Drying capacity (kg)

| Heating power (kw) | Steam heating area(m²) | Blowing rate (m3/h) | Drying tray (pcs) | Length × width × height (m) |

CT- C-0 | 25 | 9 | 10 | 3400 | 16 | 1.4*1.2*1.6 |

CT- C- IA | 50 | 12 | 15 | 3400 | 24 | 1.4*1.2*2.0 |

CT-C-I | 100 | 15 | 20 | 3450 | 48 | 2.3*1.2*2.0 |

CT-C-II | 200 | 30 | 40 | 6900 | 96 | 2.3*2.2*2.0 |

CT- C-III | 300 | 45 | 80 | 10350 | 144 | 2.3*3.22*2.0 |

CT- C-IV | 400 | 60 | 100 | 13800 | 192 | 4.45*2.2*2.0 |

Model | Drying capacity (kg)

| Heating power (kw) | Steam heating area(m²) |

CT- C-0 | 25 | 9 | 10 |

CT- C- IA | 50 | 12 | 15 |

CT-C-I | 100 | 15 | 20 |

CT-C-II | 200 | 30 | 40 |

CT- C-III | 300 | 45 | 80 |

CT- C-IV | 400 | 60 | 100 |