Our stainless steel centrifuge is also called bottom discharge centrifuge, its main function is to separate liquid and solid particles.

Stainless steel centrifuge Introduction

A stainless steel centrifuge is a machine that uses centrifugal force to separate liquid and solid particles or liquid and liquid mixtures. Stainless steel centrifuges are mainly used to separate solid particles and liquids in suspensions, or to separate two incompatible liquids with different densities in emulsions. Stainless steel centrifuges can also sort solid particles based on density or particle size.

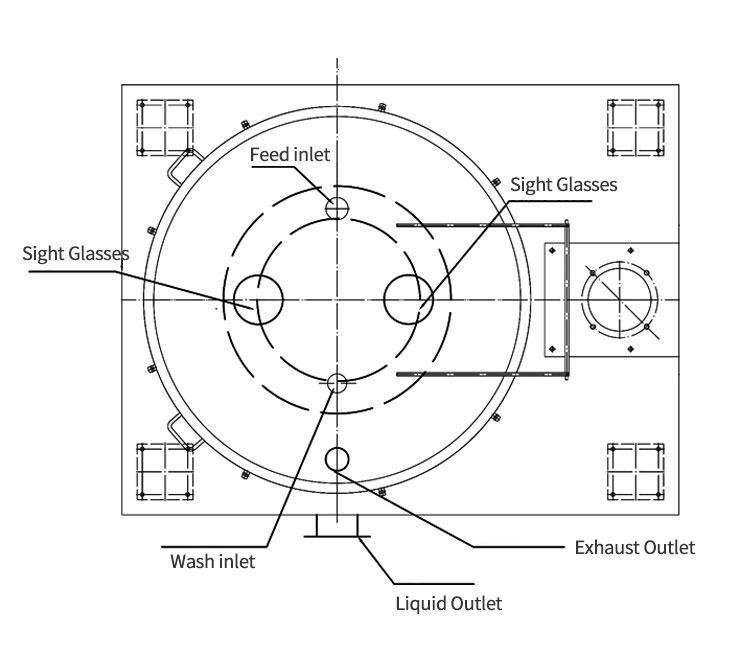

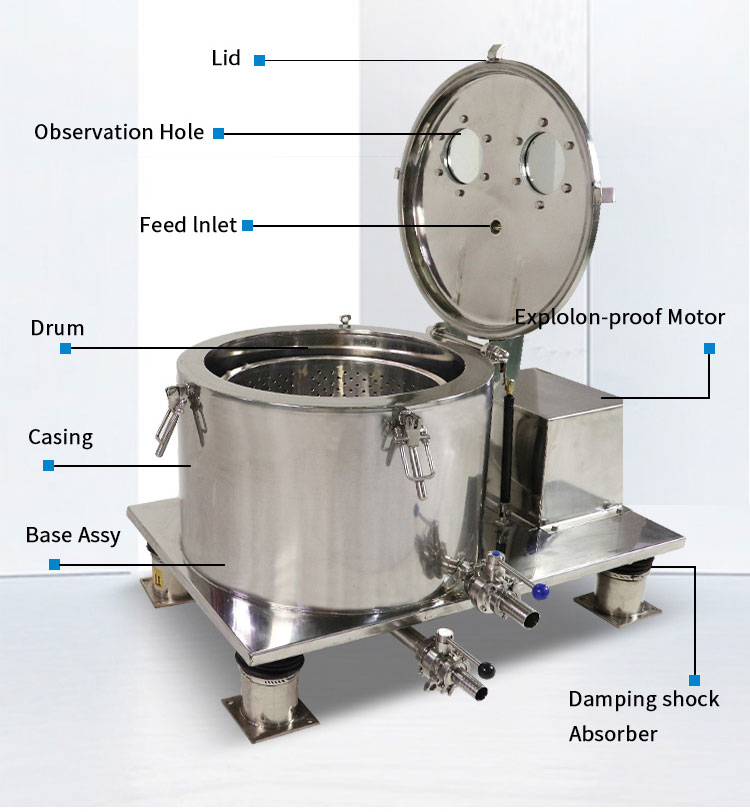

Stainless steel centrifuge structure

Our stainless steel centrifuge systems offer high quality parts with bi-directional agitation, variable speed controller (VFD - Variable Frequency Drive), resistive braking, explosion proof motors and more to ensure superior quality.

damping shock absorber

The damping shock absorber we choose has the advantages of compound vibration isolation and noise reduction, low natural frequency and good vibration isolation effect. Wide load range, long working life, safe and reliable use.

Explosion-proof motors

It can be used to generate electric sparks during operation in flammable and explosive places to ensure safe production.

Stainless steel body

Stainless steel centrifuge equipment is made of 304/316 stainless steel, and professional welding technology and sealing strips are used to ensure good sealing of the equipment and effectively avoid material waste.

Bottom discharge centrifuge advantages and features

1. Adopt frequency conversion control, stable start and adjustable separation.

2. The material particles are not easy to be broken.

3. The base and the casing are welded together, with high bearing strength.

4. The machine wall is a plane structure, which not only reduces the center of gravity of the machine, but also makes the stainless steel centrifuge run more smoothly, and the plane base can be used as an operating platform. Operation is more convenient.

5. Enclosed structure, the seals are made of silicone rubber or fluorine rubber, which can meet the requirements of sealing and explosion-proof, and is suitable for toxic, flammable and explosive occasions.

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

1)Stainless Steel Centrifuge now in stock with fast delivery.

2) Various capacities for choice.

3) With 13 years of experience in R&D and production of stainless steel reactor.

4) provide you with premium quality products and perfect after-sales service.

5) Premium quality with CE certification.

6) Factory direct sales with competitive price.

7) Provide one-stop Extraction Turnkey Solution.

How does stainless steel centrifuge works

The separation process of stainless steel centrifuge generally includes centrifugal filtration, centrifugal sedimentation and centrifugal separation.

• Centrifugal filtration

Filtration is that under the action of a driving force, the fluid in the suspension (or dust-containing gas) on one side flows to the other side through the pores of the porous medium. Particles are trapped, thereby realizing the separation process of fluid and particles.

In the first stage, the solid particles are deposited on the drum by centrifugal force, and a filter residue layer is formed on the inner wall, and the filtrate is also filtered out through the mesh of the drum by the action of centrifugal force.

In the second stage, the filter residue layer is compressed under the action of centrifugal force, and the filter pressure contained in it is squeezed out.

In the third stage, the liquid contained in the voids of the filter residue layer is continuously discharged under the action of centrifugal force, so that the filter residue is further dried.

• Centrifugal sedimentation

Under the action of centrifugal force, the suspension added to the drum forms an annular liquid layer in which solid particles settle on the drum wall to form a sediment. The clarified liquid is discharged through the overflow or skimming pipe and is called the separated liquid. At the end of separation, the sediment should be drained manually or mechanically. During settling to the drum wall, the solid particles also move axially with the liquid flow. When the feeding amount is too large, they flow to the overflow port with the liquid, and the fine particles that do not settle to the drum wall are discharged out of the drum wall with the separation liquid, making the separation liquid turbid.

Bottom discharge centrifuge application

Stainless steel centrifuge is an instrument for separating samples, which can be widely used in biomedicine, experimental research, petrochemical, agriculture, food hygiene and other fields. The analysis and separation of samples is realized by using the sedimentation speed of different substances in the centrifugal force field.

(1) Application of stainless steel centrifuge in medicine:

Stainless steel centrifuges are widely used in the medical industry. Stainless steel centrifuges are used in blood separation, virus research, DNA research, drug purification, etc. Both cells and DNA molecules require high-speed medical stainless steel centrifuges for separation studies.

(2) Application of stainless steel centrifuge in pharmaceuticals:

In the production process of some APIs, disc separators or screw unloading decanter stainless steel centrifuges are usually selected. Currently, antibiotics, vitamins, animal drugs, microorganisms, bacteria are isolated. The medicine produced by fermentation has mycelium separation process, and different products use different stainless steel centrifuges.

(3) Application of bottom discharge centrifuge in biological science.

Centrifugal technology is mainly used for the separation and preparation of various biological samples. When the biological sample suspension is rotated at a high speed, due to the large centrifugal force, the suspended small particles settle at a certain speed and are separated from the solution. The sedimentation speed depends on the quality, size and size of the particles. density.

Parameter

Mode | Diameter ( mm) | Capacity (L) | Max Load (kg) | Motor (kw) | weight (kg) |

KDCM-10 | 300 | 5 | 7.5 | 0.75 | 200 |

KDCM-30 | 450 | 20 | 30 | 1.5 | 300 |

KDCM-50 | 600 | 40 | 60 | 3 | 650 |

KDCM-100 | 800 | 100 | 135 | 5.5 | 1600 |

Mode | Diameter ( mm) | Capacity (L) | Max Load (kg) |

KDCM-10 | 300 | 5 | 7.5 |

KDCM-30 | 450 | 20 | 30 |

KDCM-50 | 600 | 40 | 60 |

KDCM-100 | 800 | 100 | 135 |